Technical Introduction of Binzhou Guangmao Chemical Technology Co., Ltd. Oilfield Technical Service Branch Company

Binzhou Guangmao Chemical Technology Co., Ltd. (hereinafter referred to as “the parent company”) Oilfield Technical Service Branch Company is a company affiliated to the parent company and is engaged in oilfield operational and matching services, including combined acid fracturing and nitrogen foam fast removal technology; water well acidizing, plugging removal and augmented injection technology for low-permeability reservoir; foam sand washing and well cleanup technology; deep profile control technology for injection well in old oilfield; water plugging for stimulation of oil in oil wells and secondary recovery technology for old wells; simulation technology of profile control by injecting nitrogen foam with steam in heavy oil reservoir and the like. With the help and support from the China University of Petroleum, the Chinese Academy of Sciences and the research institutes of major oilfields, through several years of field application, we have developed into a professional oilfield technical service company with technical strength and field operational experience. We have achieved satisfied performance and honor in Shengli Oilfield, Yanchang Oilfield, Henan Oilfield and Jidong Oilfield. We do have some actions to the development of oilfields.

1. The technology of sand washing and well cleanup by nitrogen foam flow

During the process of sand washing and well cleanup by using conventional fluid, leakage and filtration of injected fluid may lead to contamination to the pay formation and affect productivity, even normal well cleanup cycle can not be established for some wells with serious leakage. The foam flow can be applied to effectively solve above problems with its higher carrying ability.

2. Nitrogen foam acidification and acid cleaning technology

Foam acidification technology is to add foam agent and foam stabilizer into the conventional acid fluid system and form the foam fluid by mixing with the gas in the foam generator. The foam fluid is featured by both foam fluid characteristics and acidizing capacity. This technology is especially applicable to the acidizing of multilayer heterogeneous reservoir and low-pressure and low-permeability wells as well as reacidizing of old wells.

3. Hole bottom negative-pressure mixing drainage technology

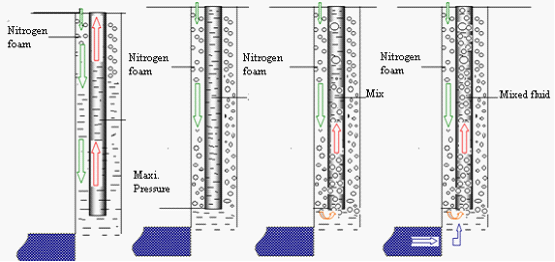

The working principle of the nitrogen foam lifting and drainage technology is to develop the uniform foam fluid with different densities by mixing and stirring the high pressure nitrogen in the foam generator and establish a circulation among production casings to discharge fluids from the wellbore; besides, with negative pressure at the bottom, the bottom fluids come from formations can be carried over, which will achieve the effects of completely removing bottom liquids and inducing oil and gas flows.

4. Steam stimulation and profile control technology for heavy oil wells

Steam-tracing nitrogen injection and high-temperature foam agent can improve the sweep efficiency and displacement efficiency of injected steam. Through adding high-temperature foam agent and nitrogen to generate rich foam among and the porous channels of formation; high-intensity foam film will lead to a sharp decrease in the permeability of gas phase and block off the high-permeability formations or large porous channels, which increases the displacement volume and the sweep area as well as improves the reservoir development effect. The researches both at home and abroad indicate that injection of high-temperature foam agent and nitrogen with steam can effectively eliminate the channeling of steam among the high-permeability zone. This is an effective manner for improving heavy oil thermal recovery ratio. Adding high-temperature foam agent and nitrogen into the steam can improve the steam-drive recovery ratio by over 20%.

5. Nitrogen foam fluid profile control and water plugging technology

Based on the principle of Jamin action, the flow resistance generated by nitrogen foam fluid in oil reservoir is much larger than that in pure gas or generated when fluid flows. This can reduce reservoir permeability, increase driving pressure differential as well as enlarge sweep efficiency and scayenging area. It can effectively adjust the injection profile. Because foam has the characteristic of blocking off water other than oil, so it has good blocking effect for large porous water passages.

6. Composite acidizing fracturing+nitrogen foam fast drainage technology for gas wells

This technology is a kind of acidizing and fracturing process through injecting prepad fluid, clean fracturing fluid and gelled acid in order (or alternately) for low filtration and deep penetration; and utilize closed acidizing to improve the flow conductivity of fractures.

The working principle of the nitrogen foam lifting and drainage technology is to develop the uniform foam fluid with different densities by mixing and stirring nitrogen in the foam generator and establish a circulation among production casings to discharge fluids from the hole bottom completely and induce flows of oil and gas. This technology has been well applied in Yanchang Oilfield. Many low productivity wells with no economic benefit have met the requirement of commercial production with 100% effectiveness and 75% of success ratio.

7. Break-down and stimulation technology for water well in low-permeability reservoir

According to the characteristics of different reservoirs and through analyzing the factors that lead to formation blockage and injection difficulties, design and develop different solutions, measures and matching technologies to increase injection capacity of water well, improve producing energy and enhance well productivity.

8. Comprehensive matching technologies for developing old wells

It refers to the technologic measures which are, subject to different types of reservoirs, different development stages and development manners, used singly or comprehensively to increase injection pressure of injectors, improve injection profile and flowline, reduce water productivity in oil well and enhance crude oil production and recovery ratio in old oilfield. Major matching technologies include the profile control technology for a single well or the deep part of block and the water-control simulation technology for oil wells.

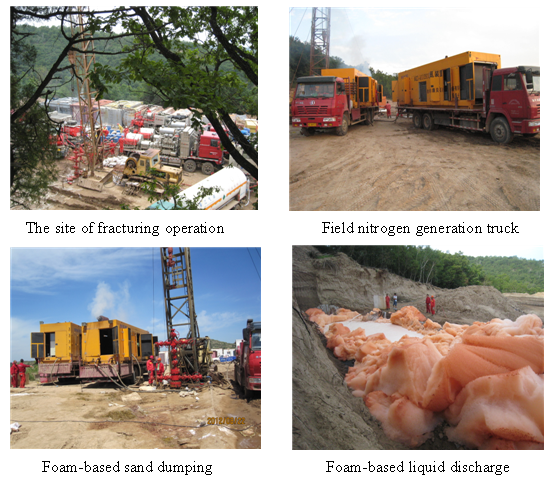

Pictures of field construction:

|